Personally, I have an experience I’d like to express in this article that entails using power tools to accomplish a personal project/job. I took on this job, not to challenge myself, but because if needed to be done. In my opinion, do it yourselfers like me should always weigh whether a job needs to be done against if it’s just another thing you are doing to fill your time.

Sometimes you may want to just get away from some other situation, and having a project/job to do may just be the right thing at the right time. Wrapping your mind and body around something physical can be the temporary escape you need. Granted, its not gonna solve any problems, but it will allow you to get away for a while…and that may be all the time you need.

The project in question is the completion of a tiling job to my covered terrace. The previous owners of this home seemed to be avid tillers. There was tile in virtually every room. The terrace that I was tiling was only about half way done, which made it look totally unfinished. It seems that these folks probably had tile left over after a job and used it when and where they could. In this case it appears that they had enough to start the job, but not finish it. So to finish it correctly…I initially tried to find a matching tile, but was unable to. No matter where I went, I couldn’t find the right color, size or texture. It’s possible that these were specially ordered.

Although my terrace is covered, it is still outside, which means it’s more susceptible to the external elements. Firstly, I chose to do this project during the coldest and wettest time of the year. Needless to say I was a slave to weather conditions. It could be wonderful weather the first half of the day and terrible the next half or visa versa. I always had to be ready to act immediately depending on the weather condition. If you are an avid do it yourselfer, I you must do a project/job during these unfavorable conditions, try to find something to do inside or away from external elements. Based on my negative experiences, it’s not worth the hassle.

Also lighting was an issue. It’s best to do some things in natural light. Because of the time I had chosen to do this (sometimes I was forced)…The sun was only up for a limited time which also hampered my efforts. In short…it got dark too soon. As my natural light faded, so did my productivity. Artificial lighting cast too many shadows and made it increasingly more difficult and hazardous to work. Don’t work with artificial light unless you absolutely must.

Finally, even though the tile cement (mortar) I had chosen was a good one and guaranteed curing during cold weather, it still took longer to cure because of the temperature, which made the job even longer to complete. Although this allowed for laying more tiles, between the weather problems, lighting issues etc., I found myself running out of time necessary for the jog at hand.

My recommendation is to give serious thought to how external elements might affect your project. And adjusting your project time to a more favorable season…may be a good decision…”JUST DO IT”, may not be the best phrase in this type of endeavor. Getting started on a project at the wrong time might hamper on entirely hinder your efforts and put a negative spin on other projects you might want to personally do.

As stated earlier, I was gonna tell you how power tools enhanced the quality and effectiveness of doing this project. First, let me say that planning is key. I first took appropriate measurements to know how much material I needed to effectively do this project. I then took stock of what tools I presently had that would be sufficient to accomplish the various tasks that this project might entail.

If you need to get additional tools for your project, you can go to [http://www.rightondoityourself.com]. Look around and order what you need. If you don’t see an item you need, just send an email indicating the absence of this item and we will try to rectify the problem.

If you can think back to using an old hand saw or manual tool, you can remember how hard it was cutting materials. Not only was it difficult to cut the material, but cutting an item in a straight line was virtually impossible.

In the old days when cabinet makers etc. cut material, they used what was available to them during their day to both make the job easier and more precise.

Today we have the addition of a motor to many devices. Cutting for instance is made much simpler by tools like saws that have motors built in. You can still buy a hand model, but why.

These motorized tools enable the common ‘do it yourselfer’ to do jobs more quickly, easily and professionally or make doing a job possible now when it would have been improbable before the advent of these motorized tools.

Some of the more common motorized tools in use today can be bought as either cordless (battery equipped) or corded. With cordless models, a tool’s ability and strength are often determined by its battery size.

Today common motorized tools are, cutters like, circular saws, reciprocating saws and routers, drills, sanders, grinders, and lathe’s etc.

Motorized tools are used throughout the world making it possible for basically anyone to try doing things that they may not have tried in the past.

Many folks are now able to build a personal small business around their ability to utilize these tools effectively. Therefore, we can note an industry creation of these small businesses. As tools become easier to use and skill sets are better defined, this relatively young industry will only expand and possibly morph into something we cannot yet see, but will eventually depend on individually as separate and independent persons with varying needs.

Just recently, I had to have some work performed at my home, and when I looked in the local yellow pages for a craftsman, I was surprised to see independent businesses that from their own admission, not been in business long, offering the same or similar service as the more well known and established businesses. For my own peace of mind I went with an older business, but that may change as time and needs progresses.

Such small businesses that may crop up over time and as needs change might be plumbing, roofing, and general repairs. We might start to see the growth of this new industry from people who now use these motorized (power) tools to make a living.

As for the average homeowner or ‘do it yourselfer’, having these motorized tools has made doing around the home projects / jobs much easier and less time consuming. The same can be said of ‘hobbyists and do it yourselfers.

Quality:

Know your facts about your particular motorized tools when considering quality. Some things to consider are:

Reliability – will this tool do what I bought it for?

Builder – is this a creditable builder of this tool?

Power usage – cordless or corded?

Reputation of the products – does it stand behind its products?

Price

Each tool is priced differently according to a number of varying factors. There are different prices for different Types of power tools used. A general or standard price cannot be placed on different tools. Prices vary dramatically between manufacturers, before other issues are considered, like:

Size

Type

Power consumption

Intended Use

Life

Materials it’s made from

Materials it’s to be used on

Skill requirements

The prices of some

Brands:

Some of the popular brands of power tools are:

DeWalt is part of the Black & Decker Company, it is a different division

Skil - tools are usually good in quality.

Delta - power tools are usually good quality, but pricey.

Makita - power tools are usually near the top but not the best performer to last forever.

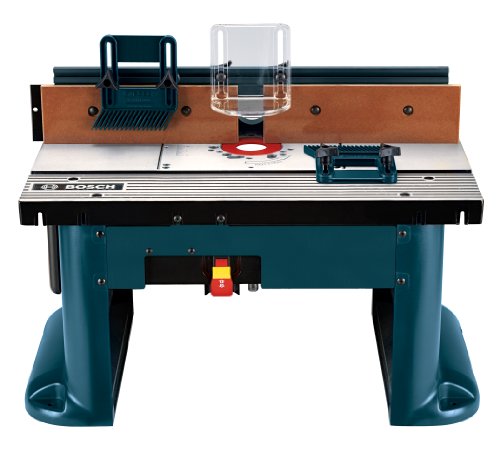

Bosch - is also a good brand.

Some of the top priced power tools are made by major manufactures like DeWalt & Porter Cable.

Craftsman – a sears product

Milwaukee – good quality, but can be pricey.

There are also other brands such as Ryobi, Panasonic, Hitachi, Delta etc.

Types:

Whatever job you need to do there is a vast variety of motorized tools at most common hardware stores like Home Depot, Lowe’s, Sears and Ace. Some of those common tools that can be found at these stores are:

Band saw

Belt Sander

Chainsaw

Circular saw

Mason saw

Disc sander

Drill

Heat gun

Jointer

Jigsaw

Lathe

Radial arm saw

Random orbital sander

Rotary tool (such as Dremel)

Router

Sander

Screwdriver

Table saw

Thickness planer

Safety:

You should read and know whatever safety requirements are needed and must be adhered to for using each tool. Needless to say that safety goggles should be worn at all times when operating motorized tools:

Do not use any tool in an explosive or flammable environment.

Inspect the tool before using it to determine that it is clean, and it works properly according to its specifications.

Prep the tool if required in the allotted time prior to use.

Do not leave a loaded ready to use tool unattended, especially where it would be available to unauthorized persons or children.

Never point the tool at anyone.

Wear ear protection if necessary.

Wear gloves when necessary.

Keep a first aid kit near by.

Good customer service is a must. With so many working parts, it is almost a given that you will need to return a motorized tool because of failure or bad manufacturing or because of another reason. With most companies today a return or exchange etc. can only be accomplished through a customer service department, so it’s imperative that they provide prompt, effective and efficient service.

Always try to plan thoroughly, but remember that there is always some unforeseen thing that will present itself. Something that you have not planned for, but you must adjust to overcome accordingly. Although planning for materials and tools is optimally important, consideration for time may also be something you’ll need to calculate.

After getting measurements and recording how much material I’d need, plus 10% extra for miscalculations and miss-cuts etc., I went to my local hardware store with my list. I bought everything I thought I would need to start, continue my progress and complete the project/job. Planning properly, appropriately and as thoroughly as possible can also eliminate extra unplanned trips to your hardware store.

As far as the extra material and or tools that are purchased, most hardware stores will accept returns of unused items. Just save your receipts…This will expedite returning materials and tools.

The power tools I used for this project were a powerful ½” electric drill with variable speeds and reverse gears. I also had a medium sized tile cutter. Some hardware stores will allow you to bring in your marked tiles to be cut for a minor price, but I like to do my own cutting. If I make a mistake…I can see my error immediately, get another piece of tile from my overage stack and re-cut without a break in my activity.

I used the drill for mixing my tile cement. The ½” bit was used to accommodate a mixing tool I got from my hardware store. I had mixed stuff by hand in the past, but trust me, electric mixing can’t be beat by time savings, muscle aches, and compound (mortar) consistency etc.

Obviously I used the tile cutter to cut tile. No need to get anything fancy (or expensive)…just make sure you get a decent to good blade. I had so much fun, cutting tiles with my tile cutter, I found myself experimenting a little with cuts I may not have tried if I did not have this electric tool.

Needless to say that electric tools can simplify and enhance our do it yourselfer activities and enable us to bring a job to completion more quickly, and hopefully give it a more professional look. Let me say that ‘Once you go Power, you’ll never go back.’